Recognizing the Importance of Fiber Dimension in Modern Industry Applications

In today's competitive landscape, you can not forget the significance of fiber measurement in your procedures. Recognizing the buildings of fibers-- like diameter, size, and density-- can directly impact the top quality and efficiency of your items. With specific dimension methods, you're far better furnished to decrease defects and maximize resource use. Exactly how do these methods align with market requirements and sustainability goals? The responses might hold the key to your success.

The Function of Fiber Measurement in Item High Quality Assurance

When you think about item quality control in markets that rely upon fiber-based products, exact fiber dimension becomes crucial. It assists you guarantee that the fibers meet specified requirements, eventually affecting the end product's honesty and capability. By gauging fiber diameter, length, and density, you can identify variances that may endanger quality.Implementing precise measurement techniques enables you to maintain limited control over production procedures, reducing the risk of defects. This not only enhances consumer complete satisfaction but likewise lessens waste and prices related to rework.Using progressed dimension devices and techniques, you can swiftly examine fiber residential or commercial properties and make notified choices, improving overall product performance. Subsequently, this positive method enhances your brand name's reputation for integrity. Ultimately, reliable fiber measurement straight adds to the longevity and success of your items in an affordable market.

Effect of Fiber Residence on Efficiency and Longevity

When you take into consideration fiber properties, strength and versatility play a crucial role in figuring out how well an item does under tension. Additionally, wetness absorption features can substantially affect toughness, especially in varying ecological problems. Thermal resistance and security are additionally crucial, as they impact the longevity and reliability of the fibers in sensible applications.

Fiber Stamina and Adaptability

Fiber stamina and versatility play a crucial duty in determining the performance and sturdiness of numerous products made use of in commercial applications. When you choose fibers, you're seeking an equilibrium in between stamina and versatility to ensure your items can hold up against stress and anxiety while preserving their form. Solid fibers stand up to breakage under tension, making them optimal for load-bearing applications. On the other hand, adaptable fibers permit motion and flexibility, which is crucial in textiles and composites. If you optimize these homes, you improve the overall capability and longevity of your products. By comprehending the certain needs of your application, you can select fibers that provide the right mix of stamina and versatility, ultimately improving product efficiency and dependability in requiring atmospheres.

Dampness Absorption Characteristics

Wetness absorption characteristics greatly affect the efficiency and toughness of fibers in different industrial applications. When you think about fibers, their capacity to absorb dampness can figure out just how well they'll carry out under various conditions. High dampness absorption may result in swelling, which can influence the fiber's toughness and versatility. It can also promote mold and mildew or mold growth, compromising the product's stability. On the other hand, reduced moisture absorption can improve toughness, making the fibers more immune to ecological aspects. You'll want to choose fibers based on their moisture absorption residential properties to guarantee peak efficiency in your particular application. By doing so, you can substantially enhance the longevity and reliability of the end product, inevitably improving its worth in the industry.

Thermal Resistance and Stability

While taking into consideration the performance and sturdiness of materials, thermal resistance and security play substantial functions in fiber applications. You require to evaluate just how fibers respond under varying temperatures, as this can directly influence their longevity and performance. High thermal resistance suggests that fibers can withstand severe warmth without degrading, making them appropriate for applications like insulation and automobile components. Additionally, stability assurances that fibers maintain their buildings gradually, even when subjected to fluctuating thermal conditions. By measuring these characteristics, you can select the ideal materials for your particular needs, assuring peak efficiency. Bear in mind, the appropriate fiber residential or commercial properties can enhance resilience and lower upkeep expenses, ultimately causing better overall item performance.

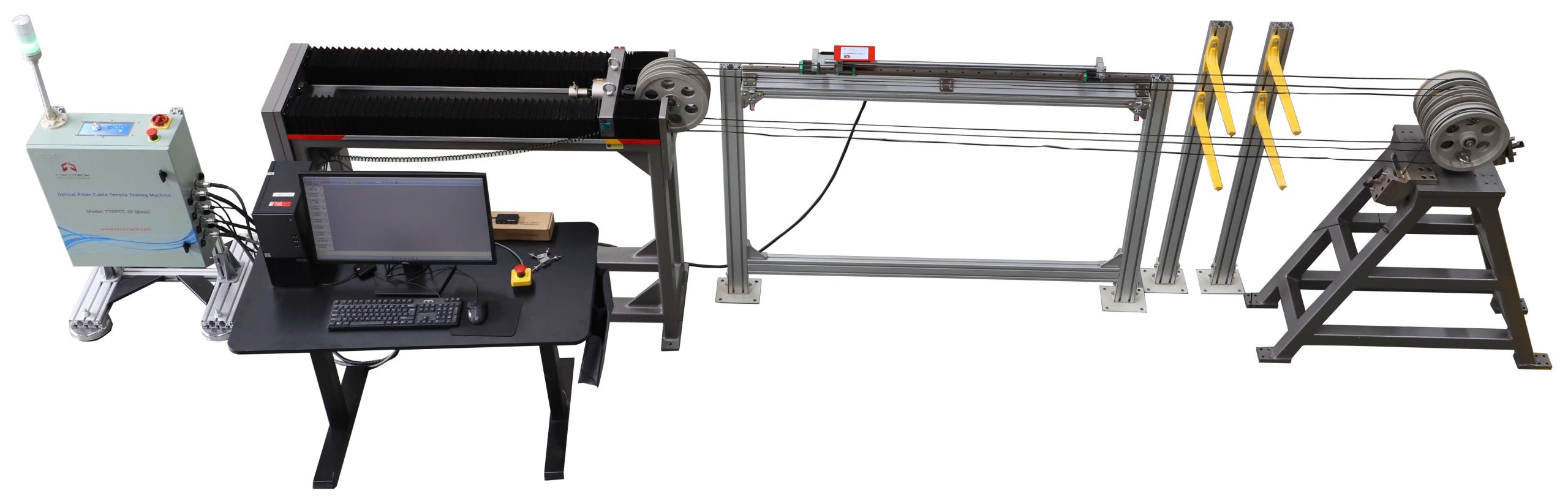

Methods and Technologies for Accurate Fiber Measurement

When measuring fiber properly, employing the right strategies and innovations is crucial for achieving reputable outcomes. You can start by utilizing optical microscopy, which allows you to observe fiber framework and morphology with accuracy. Next, consider using laser diffraction methods for identifying fiber diameter, as they use quick and non-destructive measurement.Another effective strategy is the use of image analysis software program, which automates the handling of fiber pictures, boosting precision and performance. You need to likewise check out advanced techniques like dynamic mechanical evaluation (DMA) to analyze mechanical residential or commercial properties and performance under numerous conditions.For real-time tracking, incorporating sensors with electronic data purchase systems can provide continuous fiber dimensions, guaranteeing consistent top quality control. Ultimately, always keep calibration and recognition methods for your measurement tools to validate precision. By integrating these techniques and modern technologies, you'll accomplish reliable fiber measurements important for your market applications.

Industry Criteria and Conformity in Fiber Measurement

When it concerns fiber dimension, comprehending industry standards and compliance is crucial for your procedures. You'll require to stay informed regarding regulative needs that impact your processes and warranty that your dimension strategies line up with well established criteria. This not just aids preserve high quality yet also enhances your reputation in the marketplace.

Regulatory Compliance Demands

As sectors progressively rely upon fiber dimensions, recognizing regulatory conformity needs comes to be vital for assuring item high quality and safety and security. You need to remain informed regarding specific laws that regulate fiber testing and dimension in your field. Conformity with these regulations assists stay clear of expensive fines and guarantees that your items satisfy security criteria. Key policies might consist of those set by organizations like ASTM, ISO, and ANSI, which lay out techniques for precise fiber dimension. By sticking to these standards, you not only enhance item stability yet likewise foster depend on with clients and stakeholders. It is very important to apply strenuous screening procedures and keep ideal documents to show conformity, guaranteeing you fulfill both lawful and market needs efficiently.

Standardization of Measurement Techniques

Standardization of dimension strategies is important for accomplishing regular and reliable fiber assessments across different markets. When you adopt standard methods, you guarantee that your measurements straighten with market standards, making your outcomes similar and reliable. This consistency aids in quality control, enabling you to recognize variances rapidly and take restorative actions. It likewise simplifies conformity with governing demands, as standardized techniques often meet or surpass sector norms. By implementing these methods, you enhance your credibility with stakeholders and consumers, cultivating rely on your products. Furthermore, standard techniques can streamline training processes for your team, enabling them to end up being much more skillful in fiber measurement. Eventually, welcoming standardization can cause boosted functional efficiency and far better overall results.

Enhancing Production Effectiveness With Fiber Measurement

To boost manufacturing performance, integrating fiber measurement into industrial processes can make a substantial difference. By properly determining fiber properties, you can optimize raw product usage and decrease waste, directly influencing your base line. You'll find that specific fiber dimensions assist improve production by ensuring consistency in item quality, which minimizes downtime and rework.When you carry out real-time fiber measurement modern technologies, you obtain immediate understandings into your procedures. This enables you to make quick modifications, improving throughput and enhancing overall effectiveness. Additionally, comprehending fiber attributes can lead to far better maker settings, decreasing energy intake and boosting devices lifespan.Ultimately, efficient fiber dimension equips you to make data-driven choices, bring about smoother procedures and greater efficiency. By prioritizing fiber measurement, you're not just enhancing effectiveness; you're establishing the foundation for lasting success in your industry.

The Link In Between Fiber Dimension and Sustainability

Integrating fiber dimension not only improves production efficiency but also plays an essential duty in advertising sustainability within industrial procedures. By properly measuring fiber web content, you can minimize waste and maximize source usage. This implies you're not just conserving products but additionally reducing power consumption and look at this web-site greenhouse gas discharges connected with production.When you comprehend the fiber attributes in your products, you can make informed decisions that lead to more sustainable methods. For instance, making use of the appropriate fiber blends can improve product durability, which subsequently lowers the regularity of replacements and lowers total environmental impact.Moreover, specific fiber measurement assists in compliance with sustainability regulations, making certain that your procedures straighten with environment-friendly requirements. As consumers increasingly prioritize sustainable items, your commitment to liable fiber measurement can enhance your brand credibility and satisfy market needs. Stressing sustainability through fiber dimension can cause a more reliable, accountable, and profitable operation.

Future Trends in Fiber Measurement and Industry Technology

As markets evolve, staying in advance in fiber measurement modern technology ends up being crucial for technology and page competitiveness. You'll see that innovations in automation and expert system are driving much more precise and reliable measurement procedures. Welcoming these innovations permits you to minimize mistakes and improve efficiency, providing you a side over competitors.Moreover, the assimilation of real-time data analytics is transforming exactly how you monitor fiber high quality and performance. With split second insights, you can make informed decisions that bring about improved product end results. Sustainability patterns are most likely to press innovations in environmentally friendly fiber materials, requiring exact dimension methods to assure conformity and quality.In addition, anticipate to see increased use smart sensing units that give constant surveillance, enabling for aggressive adjustments in production. By embracing these future fads, you'll place your service to thrive in an ever-evolving landscape, guaranteeing you satisfy both market needs and sustainability objectives.

Often Asked Inquiries

Just How Does Fiber Dimension Influence Consumer Security Regulations?

Fiber dimension directly affects customer safety and security policies by guaranteeing products satisfy high quality requirements. It aids identify harmful contaminations, guiding manufacturers to give more secure goods. You profit from these laws via improved item safety and transparency.

What Industries Prioritize Fiber Measurement the Most?

Are There Any Health Dangers Associated With Unreliable Fiber Dimensions?

Yes, imprecise fiber dimensions can result in health risks like digestive problems and nutrient deficiencies. optical fibre diameter analyzer. It's essential you ensure precision in fiber material, as inappropriate degrees can influence your total health and wellness and well-being

How Can Small Companies Implement Fiber Dimension Practices?

You can begin by buying trusted fiber measurement devices, educating your staff on helpful hints ideal practices, and regularly examining your items. Working together with experts can additionally help assure precision and boost your general high quality control processes.

What Are the Expenses Connected With Fiber Measurement Technologies?

The expenses related to fiber measurement modern technologies vary widely. You'll require to assess tools, upkeep, training, and prospective software application (optical fibre diameter analyzer). Spending wisely can boost item high quality, but make certain you spending plan accordingly for long-lasting benefits